-

首页

-

关于我们

-

产品展示

-

装载机配件

-

压路机配件

-

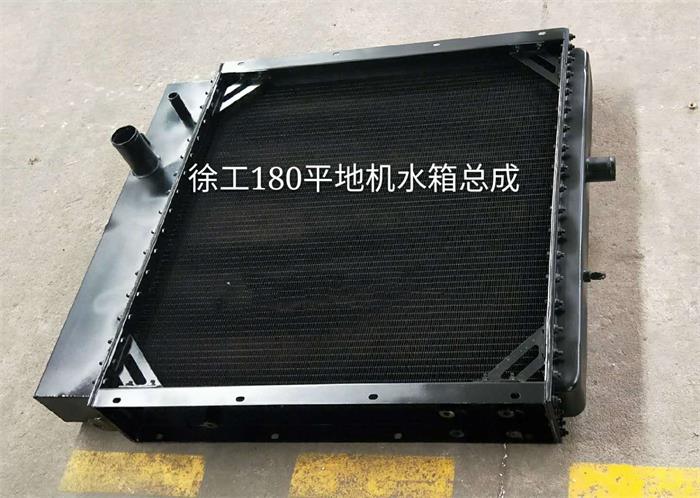

徐工平地机配件

-

徐工吊车配件

-

挖掘机配件

-

摊铺机配件

-

徐工重卡配件

-

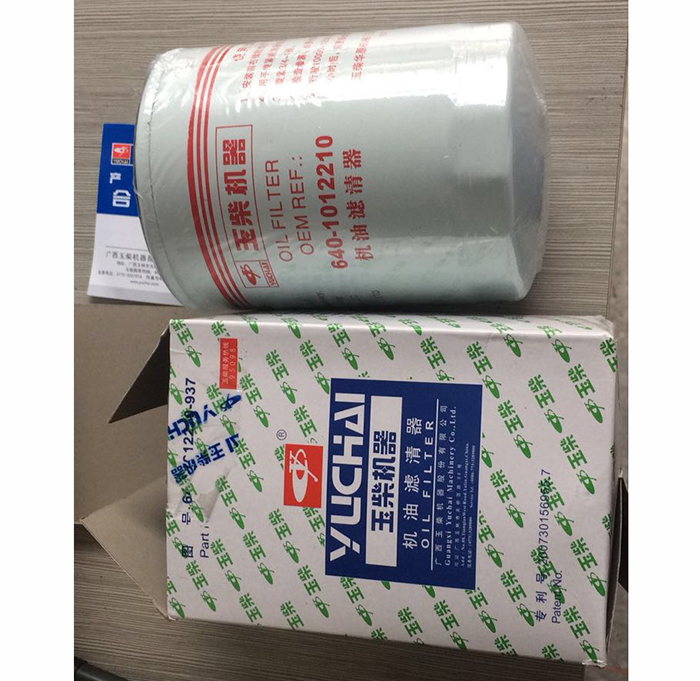

玉柴滤芯

-

玉柴滤芯

-

玉柴滤芯

-

玉柴滤芯

-

玉柴滤芯

-

玉柴滤芯

-

玉柴滤芯

-

玉柴滤芯

-

玉柴滤芯

-

玉柴水泵

-

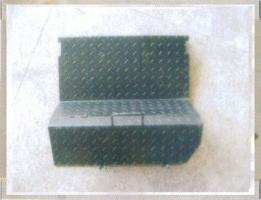

操作室

-

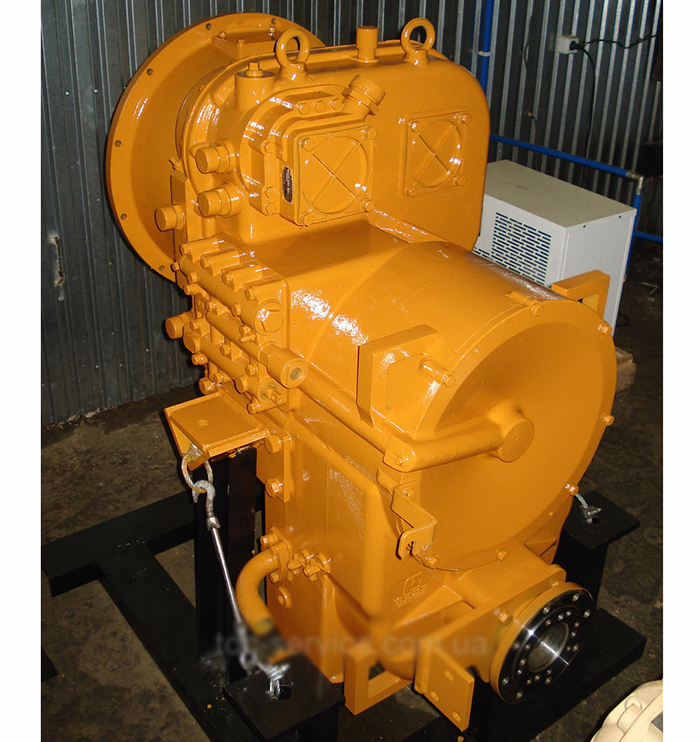

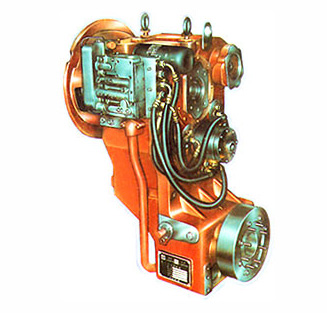

4WG180变速箱

-

2BS315A变速箱

-

300K2BS315(d)111变速箱

-

300K水箱

-

253010730可换刀版

-

272200259变速箱

-

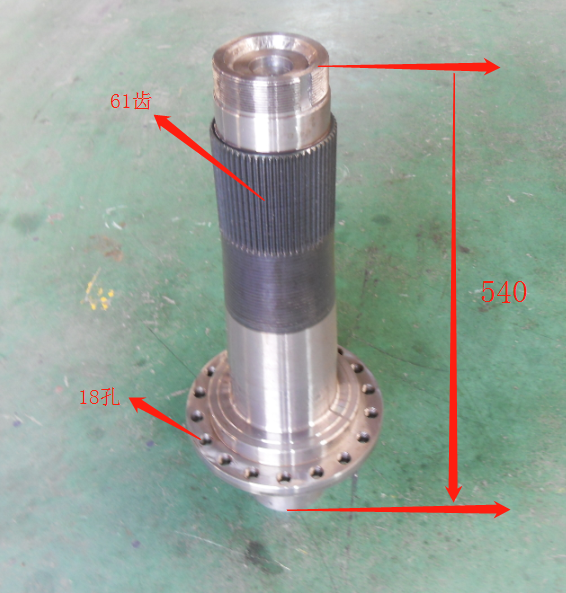

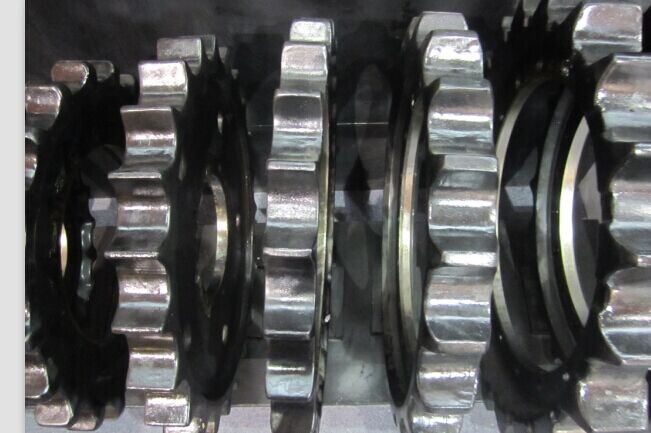

272200262轴齿轮

-

272200591变速箱

-

800302232钢圈

-

275101787 前桥总成

-

座椅

-

组合开关

-

装载机原厂刹车片

-

装载机油缸

-

装载机销轴

-

装载机门锁

-

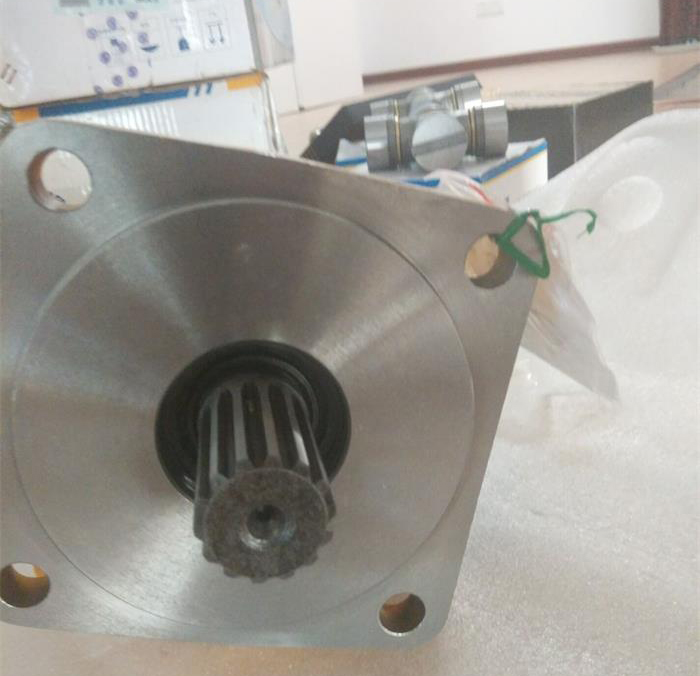

装载机电机

-

装载机ZF4WG200

-

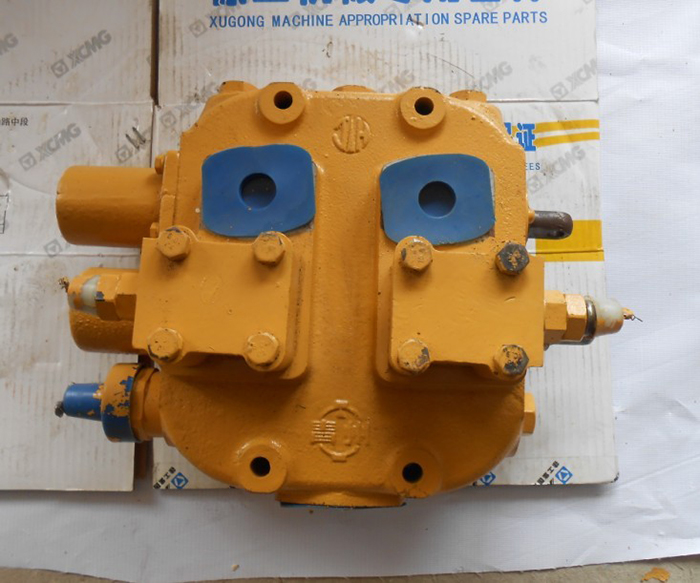

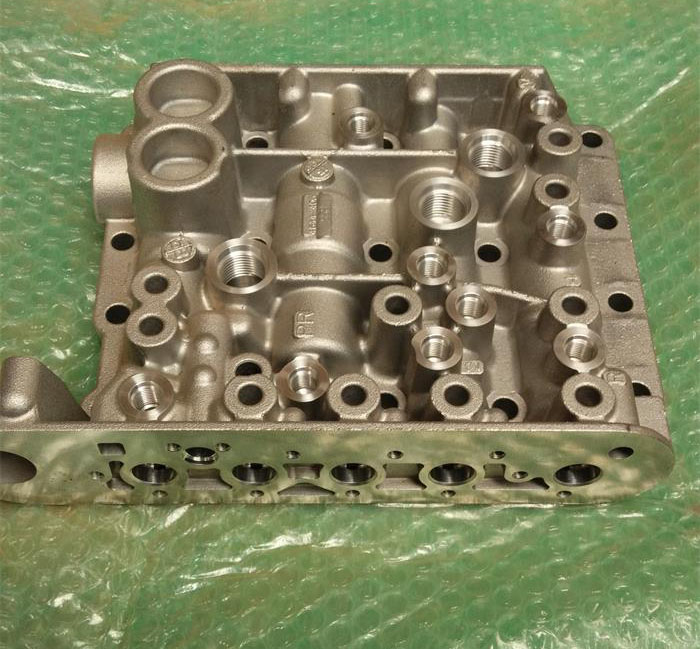

转向液压分配阀

-

转向器

-

转速表

-

主减

-

中罩

-

中桥主减

-

中间护套9337992

-

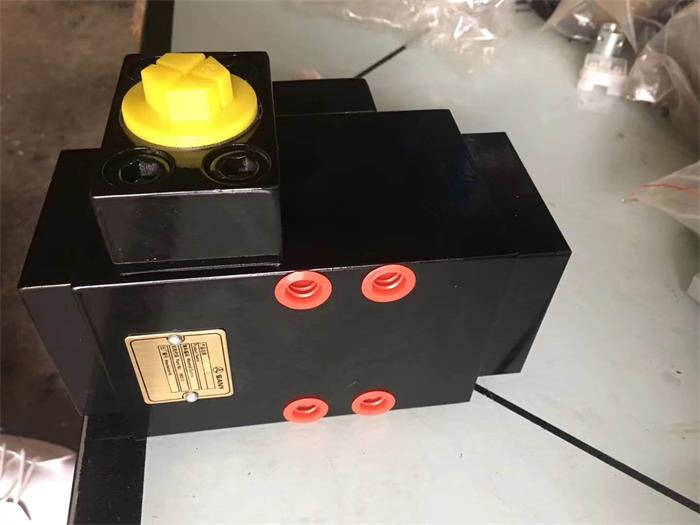

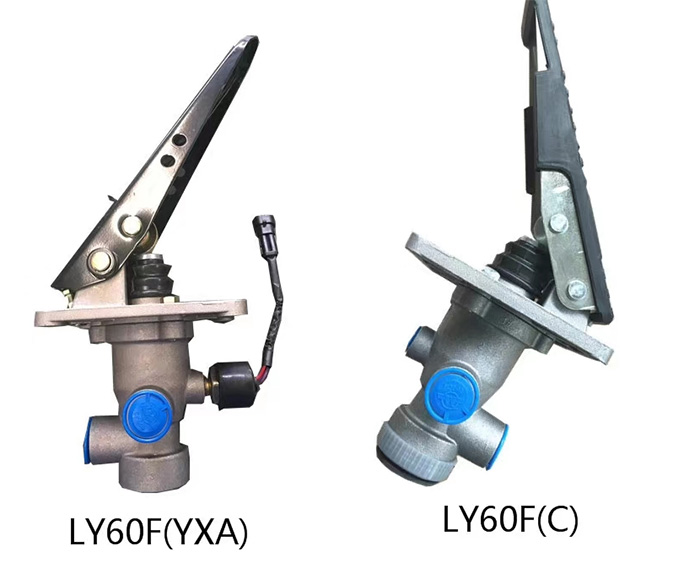

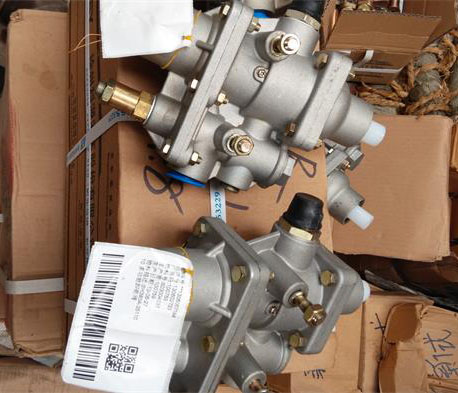

制动阀

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

操作室

-

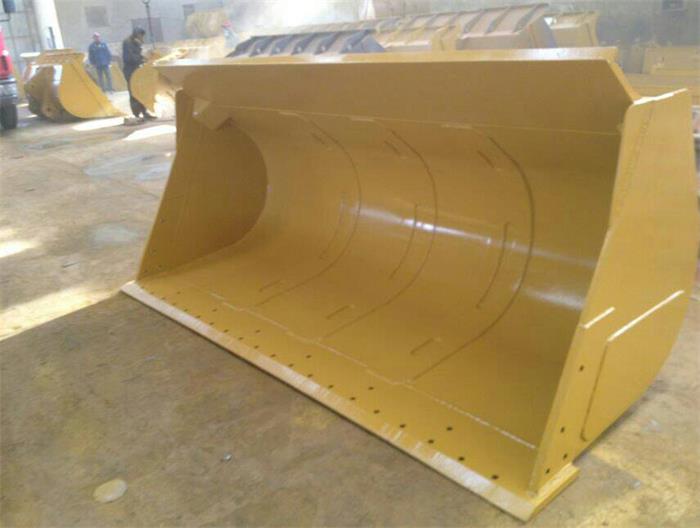

铲斗

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

装载机配件

-

2脚制动阀800901158

-

5 002

-

30-25斗齿

-

30变速箱800302352

-

30机滤总成带座

-

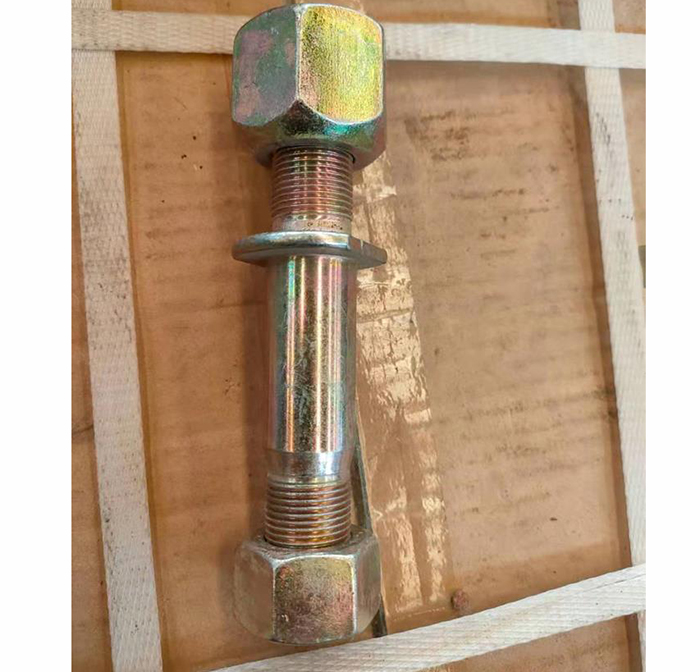

30轮辋螺栓

-

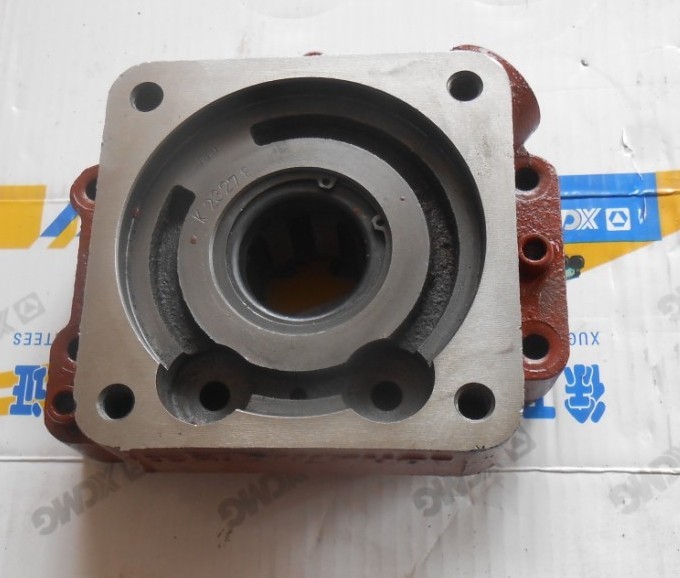

30主传动

-

30转向油缸

-

50G500制动盘860115211

-

50G动臂252108822

-

50G减震垫

-

50G老式仪表盘总成9345383、252102712

-

50G冷凝器860114138

-

50G冷凝器风扇860108026

-

50G前传Z5G.1.2

-

50G水箱

-

50G转向器125

-

50K新款散热器I

-

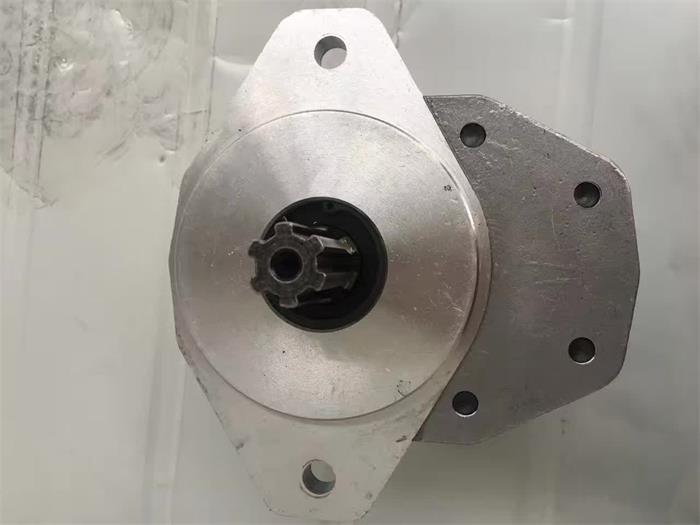

50变速泵860115020

-

50轮辋螺栓

-

50桥总成

-

50主减

-

50组合阀

-

120操作室

-

188刹车片

-

188刹车钳

-

300FN前传新款

-

300F缸床垫

-

300F驾驶室

-

300F空滤帽

-

300F全车垫

-

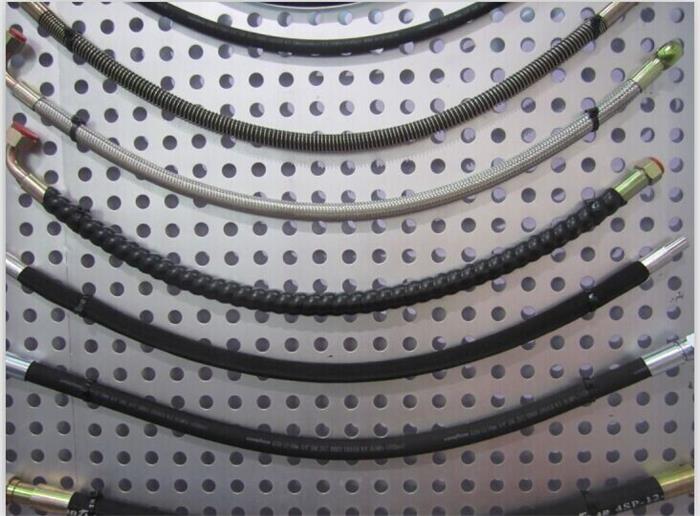

300F刹车管前

-

300F水箱

-

300F制动管

-

300F转向803004125器

-

300F装载机空调

-

300K双变总成

-

321转向器251900192

-

500C转向器

-

500FN桥总成

-

500F机油冷却器

-

500KL铲斗

-

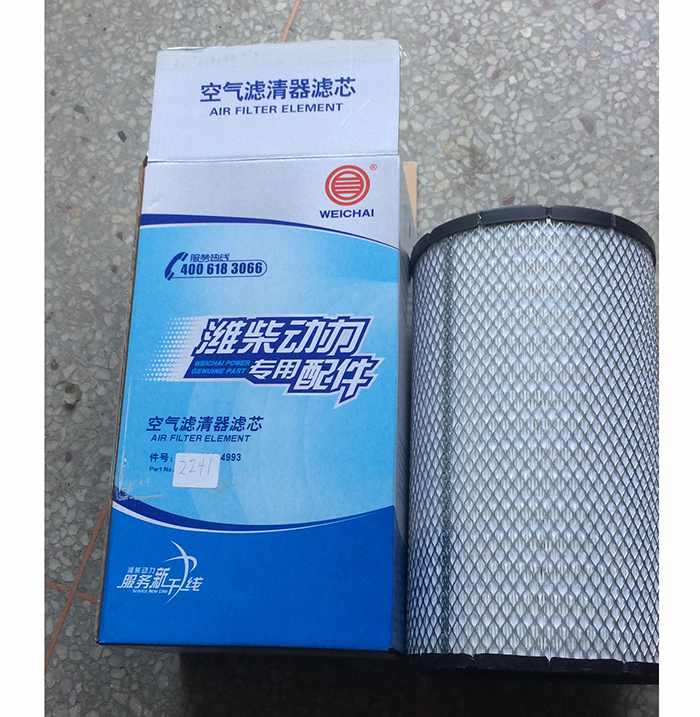

500KL空滤总成

-

500KV刹车管

-

500K老式蒸发箱

-

500K前传

-

500K水箱

-

500K新式蒸发箱

-

500K岩石斗

-

500K雨刮电机

-

500K雨刮片

-

953铲斗2

-

2440空滤器总成

-

2640空滤

-

08086-10000启动开关

-

3932545熄火电磁阀康明斯

-

5001379后尾灯803502424

-

5002028双联泵803004539

-

5005457徐工新式后尾灯803502518_

-

9304904老式斗齿

-

9314932回油滤芯

-

9321675

-

9322646前传动轴252102589

-

9324873后传动轴252102600

-

20140804_151739

-

20141021_144609

-

80388831储液罐

-

82281600主减速器总成

-

82290500主减速器总成

-

227301561后传500K

-

250100112转向器

-

250200143盘式制动器

-

250900141滑叉

-

250900324夹木钳

-

251800363前传

-

251805364后传

-

252100553转斗油缸

-

252100848高卸转斗油缸

-

252102173前传50G6

-

252110419前传50G

-

252113083前传50G

-

252113084支架

-

252900464中传

-

252900486

-

252906871前传500K

-

252906872中传500K

-

253004277轮辋60总成

-

253401276顶灯

-

272100636双联泵

-

272200752新款双变

-

275100243索玛钳仓库

-

275101705三孔新式制动器

-

275101723十字轴

-

275101966新款两孔制动钳

-

800101763散热器300F

-

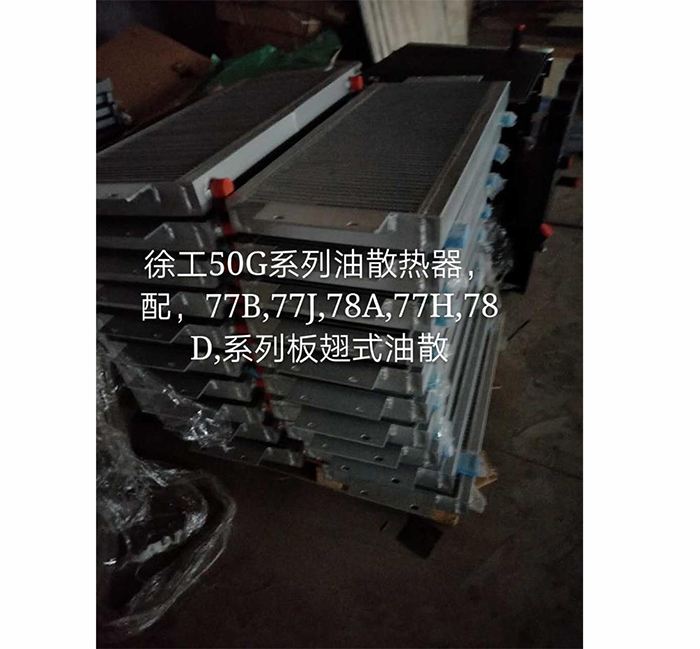

800305592水箱XGSX01-78A散热器

-

800358328散热器总成30的

-

800901151手控制动阀

-

800901161加力泵

-

800901175制动阀

-

800902558加力泵

-

803004038卸荷阀

-

803004040三联阀

-

803004079双联泵

-

803004120先导阀

-

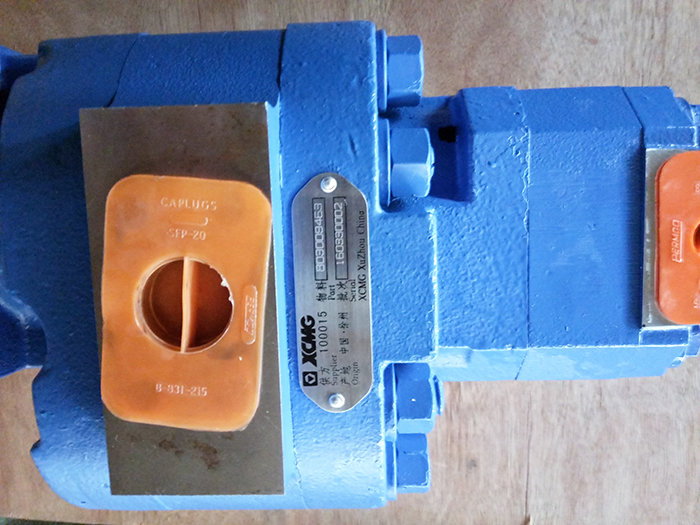

803004128工作泵

-

803004137工作泵

-

803004213双联泵

-

803004299夹钳油缸

-

803007027燃气泵

-

803009463双联泵

-

803010171马达

-

803013093双联泵

-

803044044组合仪表

-

803071237动臂油缸

-

803080926转向油缸

-

803081517动臂油缸

-

803082926转向油缸左右

-

803083410转斗油缸

-

803083775变量泵

-

803084026夹钳油缸

-

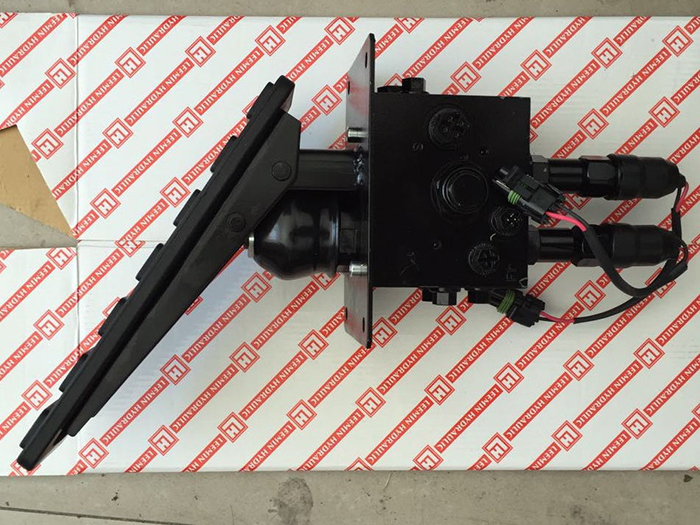

803086379先导手柄

-

803090251单手柄

-

803300970带锁加油滤网

-

803502505压力开关0.8ARR

-

803502517小时计98314

-

803544044仪表组合

-

803545324电子报警灯

-

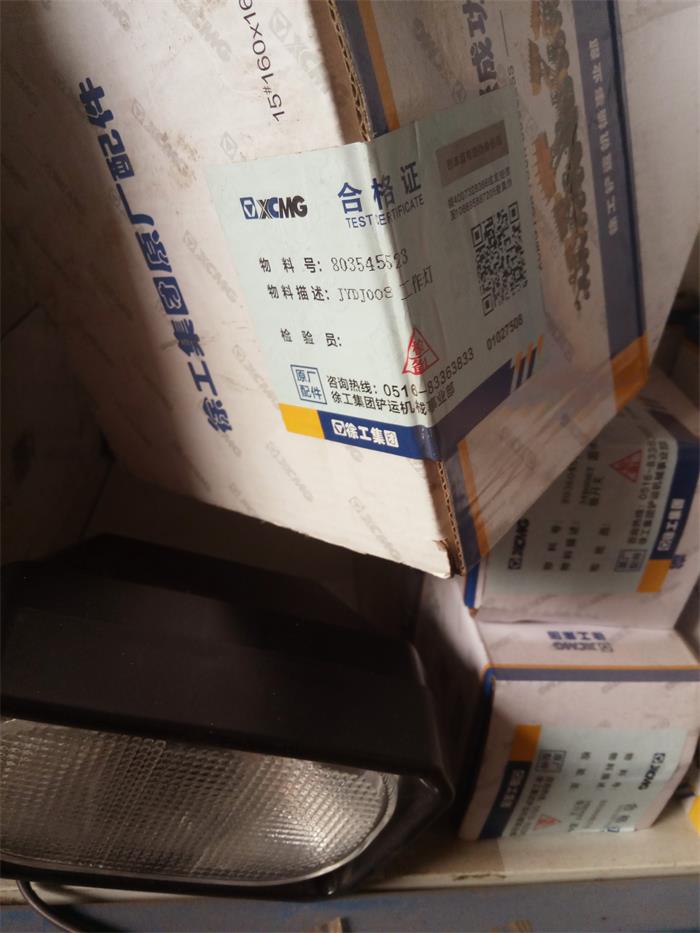

803545523工作灯

-

803545524后尾灯

-

803545526工作灯

-

803546482新款灯

-

803587850翘板开关

-

803587881-空调控

-

803588835空调控制器

-

803589289仪表盘500FN

-

803604516驱动器

-

803604579蓄电池开关

-

803680178电器集中控制盒

-

803688233油门踏板

-

860100620

-

860100624液力传动油

-

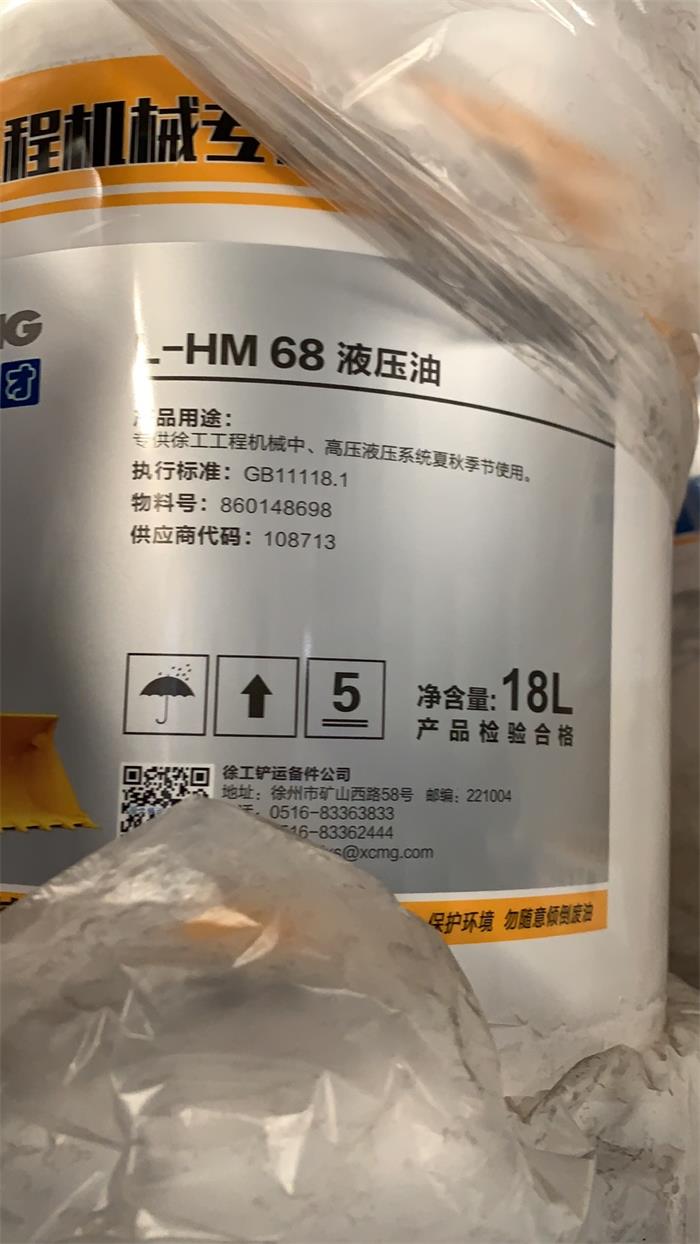

860100628抗磨液压油68#

-

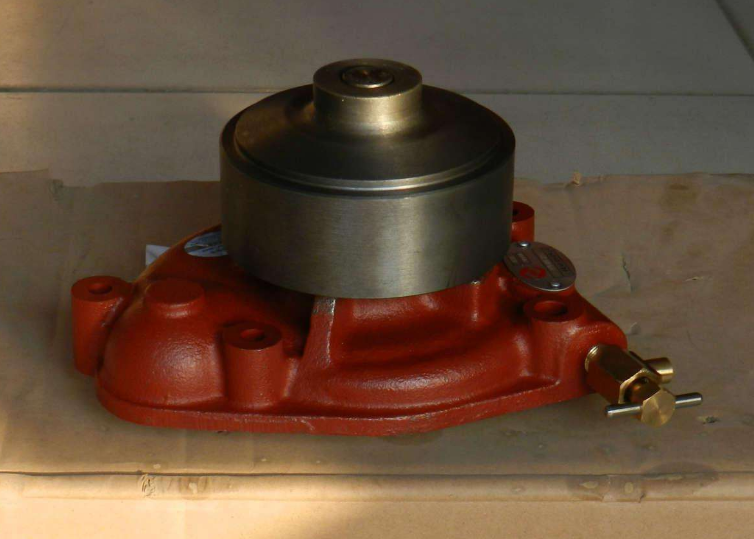

860106579上柴水泵

-

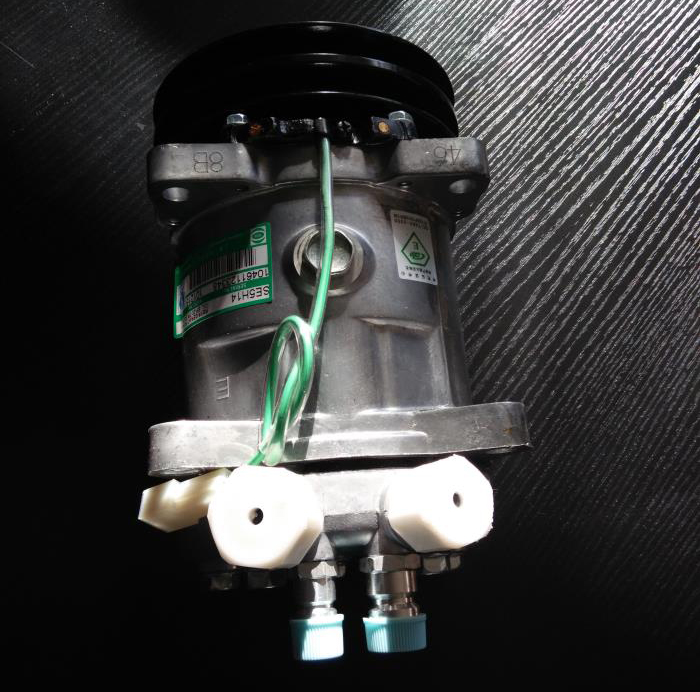

860111859空压机

-

860113253柴滤

-

860113858内胎

-

860113862万向节

-

860115187差速器总成

-

860117589潍柴增压器

-

860119080挡选

-

860119082挡选

-

860120525上柴水泵

-

860121390潍柴增压器

-

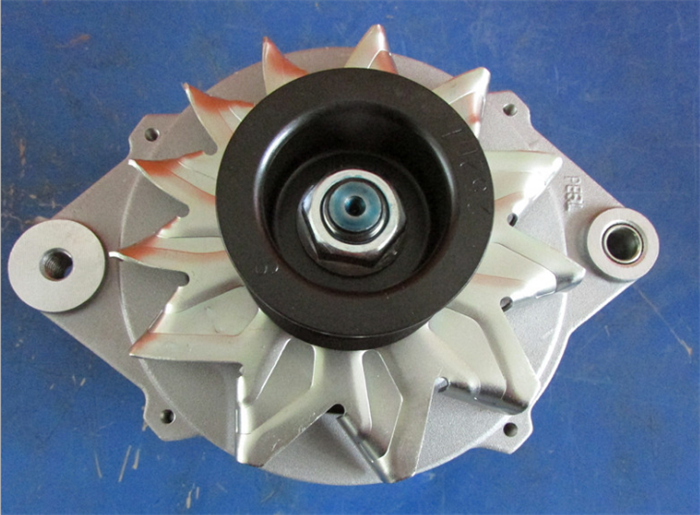

860122881上柴发电机

-

860126559机滤

-

860134181电磁阀

-

860140414潍柴电脑板

-

860146834二轴总成

-

860146969空滤

-

860147036潍柴发电机

-

860147070潍柴起动机

-

860301946加力泵小

-

1030840905伸缩油缸

-

1030842589

-

1030842591

-

1654244069

-

6009010001电脑盒

-

612600090293潍柴专用起动机

-

860148698860100628抗磨液压油68#

-

BC815变速泵

-

BS428变速箱800302352(30)

-

BZZ3-125转向器250100112

-

C6121喷油泵

-

C6121喷油器

-

CBGJ2080转向泵5002029

-

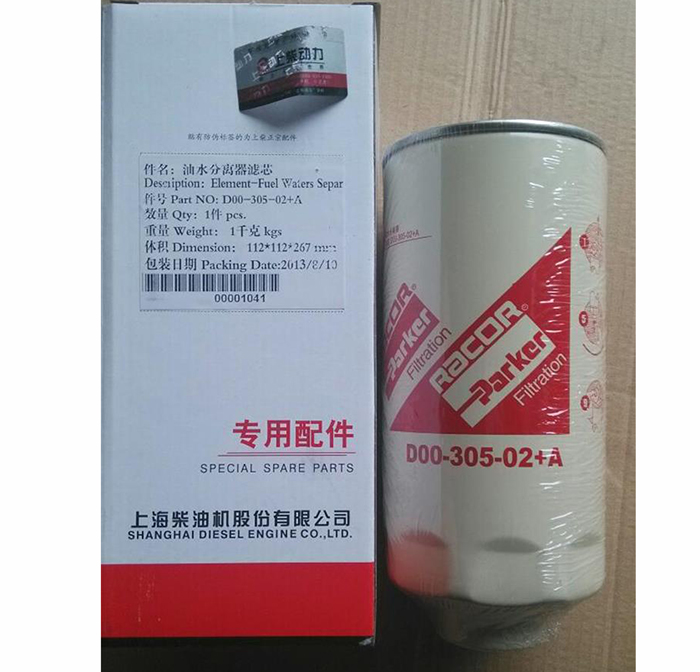

D00-305-02+A油水

-

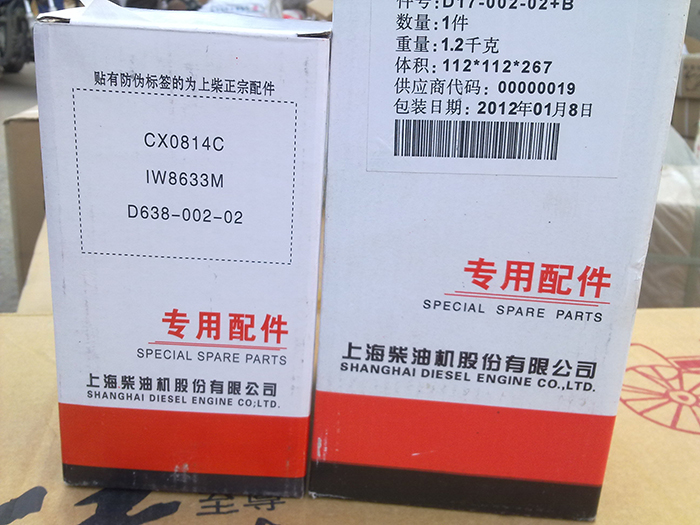

D17-002-02+B机滤

-

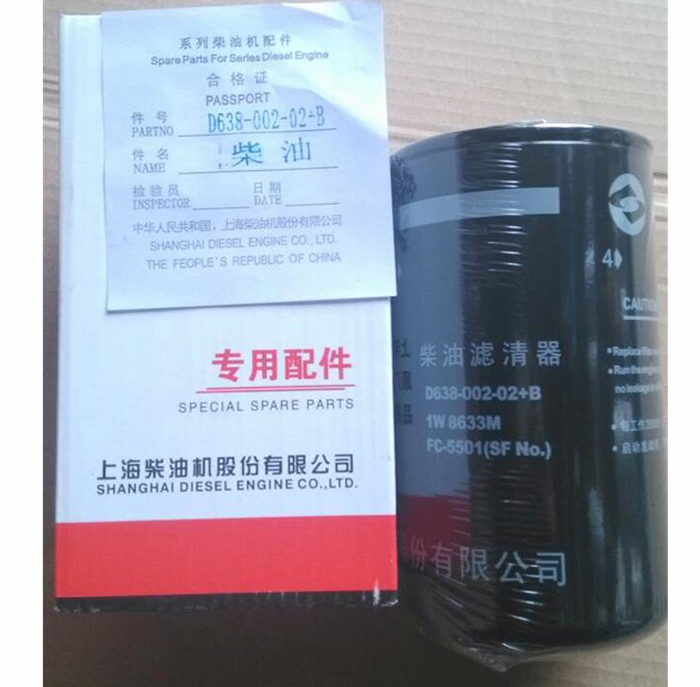

D638-002-02+B柴滤

-

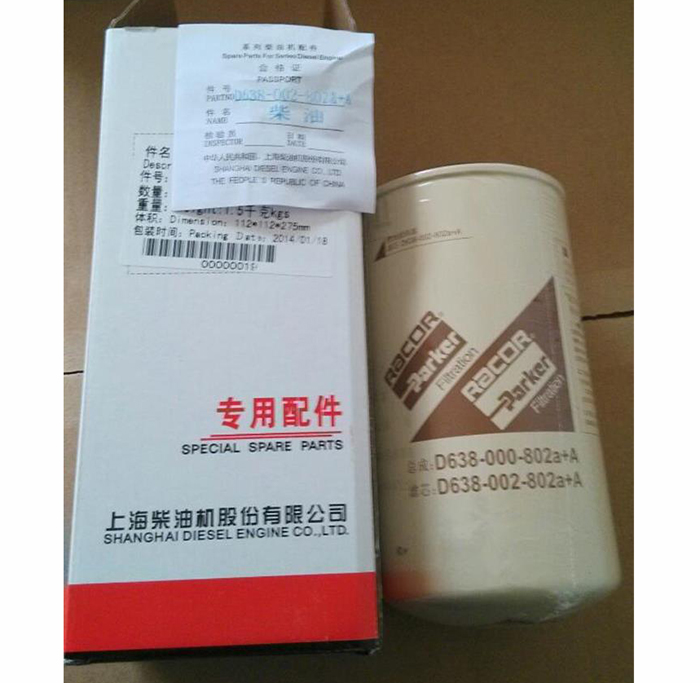

D638-002-802a+A

-

DSC00037

-

E-32泵

-

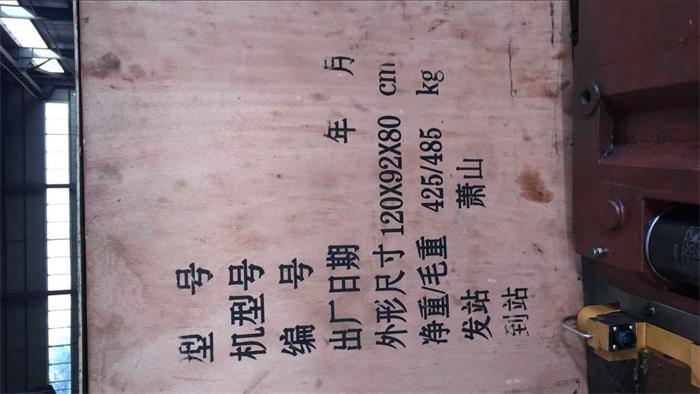

E-550包装

-

JHP2080齿轮泵

-

JHP3125泵

-

JX0818

-

KA50-5空气预滤器

-

K系列驾驶室

-

LW300FN

-

LW500F

-

LW500KL

-

SOMA刹车片860115461

-

SOMA刹车钳860115207

-

SQ-250线位性驱动器803604516

-

VDO机油表

-

VDO计时表

-

VDO加油表

-

VDO气压表

-

VDO水温表

-

VDO转速表

-

XGZZJ1226(803676118)

-

YC6105水箱散热器

-

Z00361283主减

-

Z00361284主减

-

ZF Travelling controller ZF档位控制器

-

ZL50G操纵软轴总成

-

ZL50X31变速箱总成

-

边齿

-

变矩器250200585

-

变矩器800302229

-

变矩器800302261

-

变矩器800351249

-

变速泵

-

变速箱二轴

-

变速箱总成

-

玻璃大全

-

博姆克双联泵

-

操作室

-

测压表

-

铲斗

-

齿尖

-

齿轮泵

-

传动轴

-

传动轴连接法兰

-

单稳阀

-

挡选杭齿

-

电气集中盒

-

吊车滑轮

-

吊车伸缩油缸

-

动臂油缸

-

斗齿

-

斗齿

-

短脖法兰

-

多路阀

-

二轴

-

发电机安装支架

-

方向盘喇叭按钮

-

付车架

-

钢圈(轮辋)

-

钢丝绳

-

后机罩

-

夹木钳总成

-

驾驶室

-

脚制动阀

-

进口ZF档位控制器

-

警灯

-

卷扬

-

空调

-

空调开关

-

空滤

-

空滤帽

-

拉杆

-

老式斗齿9304904边齿9321675

-

老式座椅

-

连接法兰

-

临工953铲斗

-

柳工杭齿180箱档位选择器6006040001

-

柳工液压油

-

轮边行星轮架

-

轮胎螺栓

-

罗伞齿轮

-

滤清器

-

滤芯

-

膨胀阀

-

频率传感器

-

平地机刀板

-

泊母克单泵P5100-F100

-

普通刹车钳860115346

-

起重臂IIII

-

前传动轴

-

前工作灯

-

厦工钳

-

上柴D9精滤器

-

上柴滤芯

-

上柴熄火电磁阀860109343

-

上柴曲轴前油封

-

伸缩油缸

-

手制动器总成860114980

-

索玛刹车钳860115206

-

特机仪表盘

-

挖斗

-

威力组合大灯

-

潍柴调温器860109604

-

潍柴飞轮壳

-

潍柴精滤器

-

潍柴老款熄火电磁阀

-

潍柴三滤

-

潍柴熄火电磁阀

-

潍柴涨紧轮

-

潍柴主轴瓦

-

消音器

-

销轴

-

新500KV刹车管

-

新齿尖

-

新款LED灯

-

新三孔边齿

-

新式ZF电脑盒

-

新式空滤帽

-

新型50G铲斗斗齿

-

行星轮架总成

-

徐工300F雨刮电机860115894

-

徐工挖掘机熄火电磁阀

-

徐工新式后尾灯

-

徐工液压油

-

徐工油缸

-

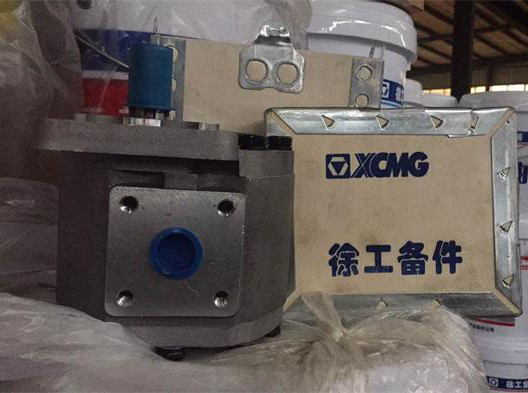

徐工原厂新泵

-

徐工自制桥

-

选配仪表盘

-

岩石斗

-

液压油缸

-

液油散

-

异形斗齿

-

优流阀

-

油门踏板

-

雨刷电机

-

玉柴柴滤

-

804025018 CP112230100230016230RA齿轮泵

-

4WG.200变速箱总成

-

6WG200ZF变速箱总成

-

165平地机变速箱总成

-

80513005花键毂860106379

-

82513600主减平衡箱

-

83513200轮边总成

-

83513201双排链轮轴

-

83513202.83763201壳体

-

83513206平地机行星轮架

-

83513208平地机齿圈支撑总成

-

85513015轴承座

-

85513019轮毂

-

85513030链轮轴

-

85513031链轮与轴组件

-

85513201双排链轮轴

-

85513400平衡箱总成

-

85763021大铜套

-

803079066制动阀波克兰

-

803506776新款大灯

-

1413380555644

-

gear ring support

-

gr100

-

gr135

-

GR135平地机

-

gr165

-

GR165变速箱总成

-

GR165平地机水箱

-

gr180

-

GR180平地机水箱

-

GR215 平地机

-

GR215

-

gr215A

-

GR215轮边总成

-

GR215

-

GR300

-

GR挡选-001

-

配件

-

配件

-

Level 杠杆

-

Leveling 找平仪

-

徐工筑路机械专用油

-

徐工平地机配件

-

徐工平地机配件

-

徐工平地机配件

-

徐工平地机配件

-

徐工平地机配件

-

Ripper teeth 后松土器齿套

-

Selector 档位选择器

-

SG-6A党选

-

Spacer Bush隔套

-

WG180变速箱体积

-

ZF053滤芯

-

ZF挡选

-

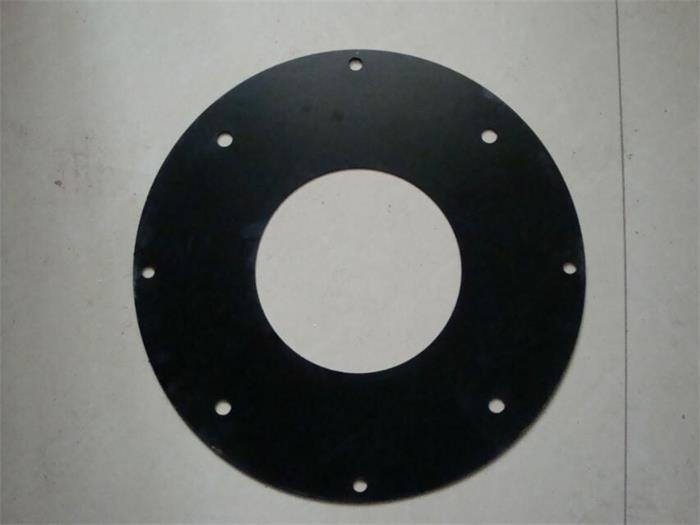

ZF法兰盘

-

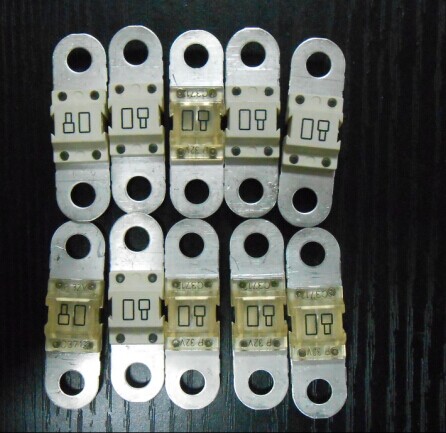

ZF摩擦片

-

多路阀

-

发动机件

-

杭齿180变速箱总成

-

杭齿档位选择器

-

轮毂Hub

-

美驰制动鼓

-

平地机变速箱

-

平地机刀板

-

平地机工厂

-

平地机老款计时表

-

平地机离合器

-

平地机轮毂

-

平地机配件

-

平地机前桥总成

-

平地机松土器

-

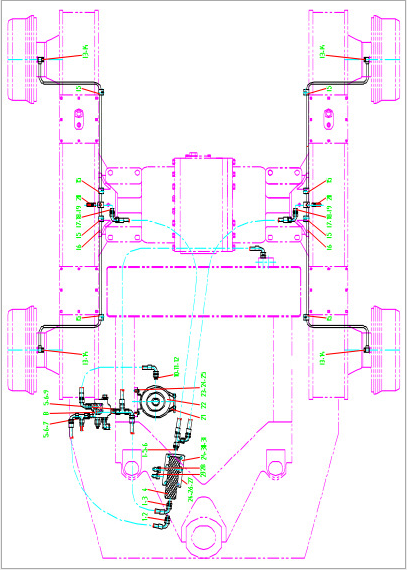

平地机液压制动系统

-

平地机油缸

-

平地机油缸球头

-

平地机制动阀进口

-

平地机自动毂

-

启动开关

-

桥总成

-

手控制动阀

-

双排链轮轴尺寸

-

锁紧螺母

-

铜导槽累

-

徐工平地机配件

-

徐工平地机配件

-

徐工平地机配件

-

徐工平地机配件

-

涡轮

-

涡轮箱

-

卸荷阀

-

新式多路阀

-

行星减速壳体Retarder hub

-

徐工天工平地机支承套

-

徐工天工平地机制动蹄

-

制动踏板

-

制动蹄

-

装载机压路机平地机驾驶室总成

-

SWE08B

-

XCG210LC-8旋转接头

-

XCMG WZ30-25

-

XE215C

-

XE470风扇叶

-

XE470风扇叶800138371

-

XE470风扇叶五十铃

-

小松PC210LC-8MO

-

Bucket Teeth 斗齿

-

Bucket 挖斗

-

Bush 衬套

-

First Reduction 一级减速器

-

Fan 风机

-

Cab 驾驶室

-

CAT保养滤芯

-

挖机保养滤芯

-

沃尔沃保养滤芯

-

Coupling 联轴器

-

Driving teeth 驱动齿

-

Evaporation 蒸发箱

-

Guard Plate 铲斗护板

-

Hose 胶管

-

Insurance Pad 保险片

-

Pilot Handle先导手柄

-

psbCAWRJ058

-

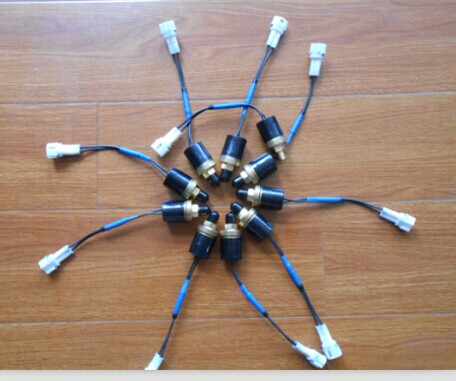

Pressure Switch 压力开关

-

川崎K3V180DT液压泵

-

Reduction shell 减速机地壳

-

Ring 钢圈

-

Sensor 传感器

-

Sun gear 太阳轮

-

Supportot 挖机背

-

Teeth 斗齿

-

Track Roller 支重轮

-

传感器

-

斗齿

-

多向转换阀

-

发动机胶垫

-

风扇叶

-

工字梁

-

工作灯

-

驾驶室

-

脚制动阀

-

接头

-

节温器

-

联轴器

-

链轨 track link

-

千秋架挖机

-

燃油传感器

-

散热器

-

挖机传感器

-

挖机电脑显示器线束

-

挖机控制器

-

挖掘机操作手柄

-

挖掘机启动钥匙

-

挖掘机四轮一带

-

挖掘机先导

-

挖掘机行走阀

-

挖掘机制动阀

-

熄火电磁阀

-

先导手柄

-

显示器

-

线束

-

销轴

-

徐挖220-8

-

液压滤芯

-

引导轮

-

油缸修理包

-

油门旋钮

-

蒸发箱

-

-

型号查询

-

新闻中心

-

服务支持

-

联系我们